제품소개

S J CCUSOTMER CENTER

Fax032-815-6801

- 토, 일, 공휴일 : 휴무

- email : sjc0143@gmail.com

ASSEMBLY SHOP

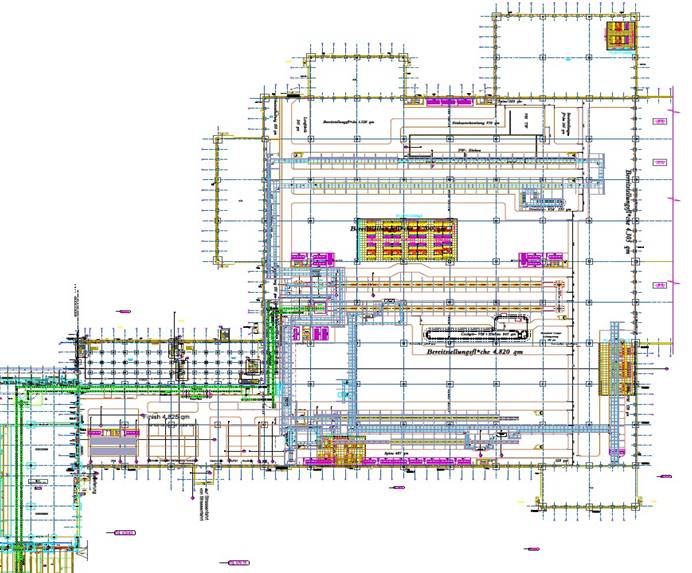

PRODUCTSASSEMBLY SHOP (LAY-OUT)

Lay-Out fo Volkswagen India

* General Specification

1. Production Capacity : 45UPH

2. Detail of Equipment :

2-1. Trim 1,2 :Floor Friction Conveyor

(with Scissors Lift)

2-2. Chassis1,2 : EMS Overhead Conveyor

(Length :800m, Hanger : 75sets)

2-3. Final1,2: Double Slat Conveyor

2-4. Finish Line: Plastic Conveyor

2-5. Door Sub Line: Power & Free Conveyor

Hanger : 150sets

2-6. Cockpit Sub Line: EMS Overhead

Conveyor(Hanger : 35sets)

2-7. FEM Sub Line: Overhead Conveyor

Hanger : 15sets

ASSEMBLY SHOP (PBS TO TRIM IN )

* Floor Platform Conveyor with Scissors Lifter VW India

* Floor Platform Conveyor with Scissors Lifter VW India

ASSEMBLY SHOP (TRIM LINE 1 )

* Floor Platform Conveyor with Scissors Lifter VW India

ASSEMBLY SHOP (FLOOR TYPE & PIT TYPE)

* TATA Motors NEW TCF 250UPD

* Floor Platform Conveyor with Scissors Lifter BHMC

ASSEMBLY SHOP (PIT TYPE)

* Floor Platform Conveyor KMC H1

TRANSFER SYSTEM (TRIM1 TO TRIM2)

* VW India Transfer System (Trim 1 to Trim 2)

TRANSFER SYSTEM (MEZZANINE & PIT RETURN TYPE)

* Cross Transfer on the Mezzanine BHMC

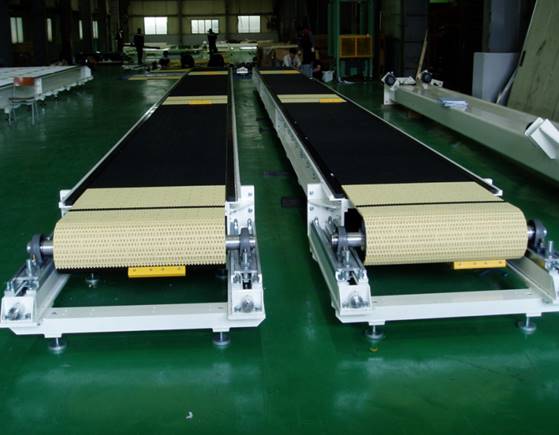

* Cross Transfer in the pit KMC H-1 (Shop test)

ASSEMBLY SHOP (CHASSIS LINE)

* Overhead Electric Monorail System VW India (Bus Bar)

* Overhead Power & Free (3 way & C-Hanger) TATA New TCF 250 UPD

TRANSFER ( CHASSIS TO FINAL )

Overhead Electric Monorail System BHMC

(Non Contact Power Supply) IPF

* Electric Monorail System KMC H1

(Bus Bar Contact Power Supply)

ASSEMBLY SHOP (CHASSIS LINE TO FINAL LINE)

* Final In Four Post Lifter VW India

ASSEMBLY SHOP (FINAL 2 LINE)

* Double Slat Conveyor VW India

ASSEMBLY SHOP (FINISH LINE)

* Single Plastic Conveyor Finish Line VW India

ASSEMBLY SHOP (FINISH LINE)

* Double Plastic Slat Conveyor for Water Test HMC/KMC R&D center

* Single Plastic Slat Conveyor for Filling HMC/KMC R&D Center

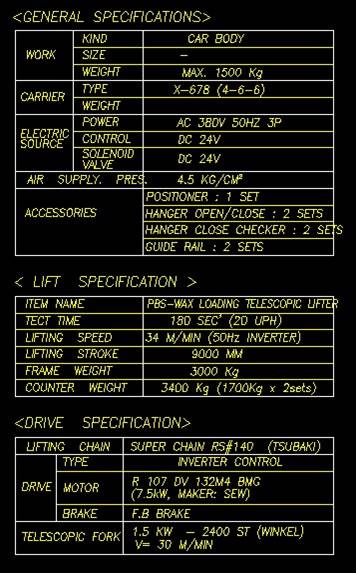

ASSEMBLY SHOP (LIFTER)

* 250UPD Four Post Lifter TATA India

* Hwasung #1 Four Post Lifter HM KMC

* Door Two Post Lifter VW India

* D4C and D8C Two Post Lifter Malaysia

• 250UPD Telescopic Drop Lifter TATA India

(Trim to Underbody)

WASHING MACHINE ASSMBLY LINE